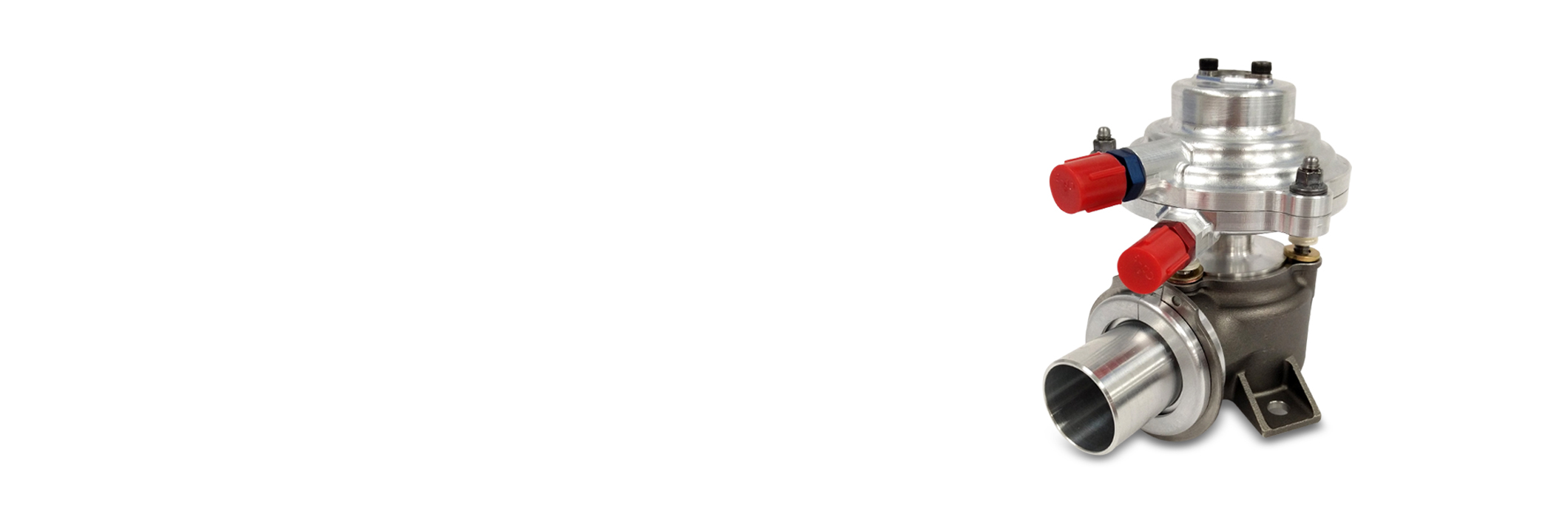

Leveraging decades of Motorsport expertise, DSPS Engineering consistently selects the ideal materials for each application by testing what works best. Our knowledge and field experience enables us to anticipate factors like thermal toughness and durability. Material choices in wastegates vary based on Technical Regulations specific to each race category.

Materials & testing

What materials are used

All assemblies created by DSPS Engineering are optimised from a material point of view, to achieve the best possible performance on track. Every component is designed to be as mass efficient as possible, without compromising reliability.

Metal alloys

Inconel 625 is used for all of the wastegate castings, whereas the ALS castings are usually Stainless Steel. Aluminium components tend to be Al 2014A T6 or 7075 T6, depending on application and the Titanium components are all Ti 6Al4V.

Stainless Steel is used extensively, and valve materials are either Stainless steel or Nimonic 80, depending on application. Material Certification is stored with all components, so that DSPS Engineering can accurately trace batch numbers.

Get in touch to discuss a project:

Testing techniques

Throughout the entire production process, all components and assemblies undergo meticulous checks to ensure the maintenance of optimum quality standards. Our commitment to excellence extends to wastegate assemblies, which can be tailored to meet specific customer requirements.

These assemblies undergo comprehensive testing not only for customer specifications but also for ongoing condition monitoring. This rigorous testing approach ensures that our products consistently meet the highest standards of performance and reliability.

Testing workflow process

There are multiple test and inspection stages in the life of our components.

When they come into our workshop, all parts are inspected to check for compliance with our drawings and standards.

When an assembly is built, there are various checks throughout the build process – ensuring reliable operation in competition.

The final assembly is then pressure checked and also visually checked.

Why DSPS

Since 1986, DSPS products have won numerous races and championships globally, competing in the highest echelons of the motorsport world - F1, Indycar, Le Mans, DTM, SGT, GT3, IMSA, WRC, RallyX, Supercars and Hypercars.

All DSPS assemblies are assigned an individual Life Number during the build process, meaning that parts are managed throughout their service life, wherever they are in the world and within the specified service conditions.

DSPS has been supporting customers for over 30 years with Championship winning products. How can DSPS help you to fulfil your motorsport dreams?

Helping you achieve the best performance

Our mission is centred around helping you achieve the best performance on the motorsport stage. Through our cutting-edge products, we provide solutions that optimise your vehicle's capabilities. Our commitment to precision engineering, innovation, and reliability ensures that our products contribute significantly to enhancing the overall performance of your racing endeavours.